F

F

I

I

N

N

A

A

L

L

K

K

N

N

K

K

T

T

.

.

1

1

0

0

.

.

0

0

9

9

.

.

1

1

4

4

.

.

0

0

4

4

N

N

A

A

T

T

I

I

O

O

N

N

A

A

L

L

T

T

R

R

A

A

N

N

S

S

P

P

O

O

R

R

T

T

A

A

T

T

I

I

O

O

N

N

S

S

A

A

F

F

E

E

T

T

Y

Y

C

C

O

O

M

M

M

M

I

I

T

T

T

T

E

E

E

E

Bali International Flight Academy

Cessna 172 Skyhawk; PK-ROG

2.4 km SW Blimbingsari Aerodrome

Banyuwangi, East Java

Republic of Indonesia

1 September 2010

Aircraft Accident Investigation Report

NATIONAL TRANSPORTATION SAFETY COMMITTEE

MINISTRY OF TRANSPORTATION

REPUBLIC OF INDONESIA

2011

This Final Report was produced by the National Transportation Safety

Committee (NTSC), Ministry of Transportation Building 3

rd

Floor, Jalan

Merdeka Timur No. 5 Jakarta 10110, Indonesia.

The report is based upon the investigation carried out by the NTSC in

accordance with Annex 13 to the Convention on International Civil

Aviation, the Indonesian Aviation Act (UU No. 1/2009) and Government

Regulation (PP No. 3/2001).

Readers are advised that the NTSC investigates for the sole purpose of

enhancing aviation safety. Consequently, NTSC reports are confined to

matters of safety significance and may be misleading if used for any other

purpose.

As NTSC believes that safety information is of greatest value if it is passed

on for the use of others, readers are encouraged to copy or reprint for

further distribution, acknowledging NTSC as the source.

When the NTSC makes recommendations as a result of its

investigations or research, safety is its primary consideration.

However, the NTSC fully recognizes that the implementation of

recommendations arising from its investigations will in some cases

incur a cost to the industry.

Readers should note that the information in NTSC reports and

recommendations is provided to promote aviation safety. In no case is

it intended to imply blame or liability.

i

TABLE OF CONTENTS

TABLE OF CONTENTS ..................................................................................................... i

TABLE OF FIGURES ....................................................................................................... iii

GLOSSARY OF ABBREVIATIONS ............................................................................... iv

INTRODUCTION ............................................................................................................... 1

1 FACTUAL INFORMATION ...................................................................................... 2

1.1 History of the Flight ........................................................................................... 2

1.2 Injuries to Persons .............................................................................................. 3

1.3 Damage to Aircraft ............................................................................................. 3

1.4 Other Damage ..................................................................................................... 4

1.5 Personnel Information ........................................................................................ 4

1.5.1 Pilot in command (Instructor Pilot) ....................................................... 4

1.5.2 Student Pilot .......................................................................................... 4

1.6 Aircraft Information ........................................................................................... 6

1.6.1 General .................................................................................................. 6

1.6.2 Engines .................................................................................................. 6

1.6.3 Propeller Information ............................................................................ 7

1.6.4 Weight and Balance ............................................................................... 7

1.7 Meteorological Information ................................................................................ 7

1.8 Aids to Navigation .............................................................................................. 7

1.9 Communications ................................................................................................. 7

1.10 Aerodrome Information ...................................................................................... 7

1.11 Flight Recorders ................................................................................................. 8

1.12 Wreckage and Impact Information ..................................................................... 8

1.13 Medical and Pathological Information ............................................................... 9

1.14 Fire ...................................................................................................................... 9

1.15 Survival Aspects ................................................................................................. 9

1.16 Tests and Research ............................................................................................. 9

1.17 Organisational and Management Information .................................................... 9

1.18 Additional Information ..................................................................................... 10

1.18.1 The Engine Teardown and Examination ............................................. 10

1.18.1.1 Engine Teardown .............................................................. 10

ii

1.18.1.2 Cylinder #2 Examination .................................................. 10

1.18.2 Maintenance ........................................................................................ 12

1.18.3 Training Manual and Operation .......................................................... 12

1.18.4 Fuel Handling Procedure ..................................................................... 13

1.19 Useful or Effective Investigation Techniques .................................................. 13

2 ANALYSIS .................................................................................................................. 14

2.1 Engine Failure ................................................................................................... 14

2.2 Fuel Alteration .................................................................................................. 14

2.3 Fuel Handling Procedure .................................................................................. 14

3 CONCLUSIONS ......................................................................................................... 15

3.1 Findings ............................................................................................................ 15

3.2 Causes ............................................................................................................... 16

4 SAFETY ACTIONS ................................................................................................... 17

4.1 Bali International Flight Academy ................................................................... 17

4.2 Directorate General of Civil Aviation .............................................................. 17

5 SAFETY RECOMMENDATIONS .......................................................................... 18

5.1 Recommendations to Bali International Flight Academy (BIFA) .................... 18

5.2 Recommendation to the Director General of Civil Aviation (DGCA) ............. 18

6 APPENDIX ................................................................................................................. 19

iii

TABLE OF FIGURES

Figure 1: PK-ROG on rice field about 2.4 km SW from Blimbingsari Aerodrome .................... 3

Figure 2: The aircraft’s propeller and nose landing gear were damaged .................................... 8

Figure 3: Organisation structure .................................................................................................. 9

Figure 4: De-lamination of coating. .......................................................................................... 10

Figure 5: De-laminations started earlier from location near the TDC as indicated ................... 11

Figure 6: The cylinder surface shows fine scratch lines which were intended to improve

the mechanical binding of the coating. A small metallic particle is observed at

position near 13.7mm of the ruler ............................................................................. 11

Figure 7: Blister of long type found near the BDC (Bottom Dead Centre). Cracks started

to develop at the blister ............................................................................................. 12

iv

GLOSSARY OF ABBREVIATIONS

AD : Airworthiness Directive

AFM : Airplane Flight Manual

AGL : Above Ground Level

ALAR : Approach-and-Landing Accident Reduction

AMSL : Above Mean Sea Level

AOC : Air Operator Certificate

ATC : Air Traffic Control

ATPL : Air Transport Pilot License

ATS : Air Traffic Service

Avsec : Aviation Security

BMG : Badan Meterologi dan Geofisika

BOM : Basic Operation Manual

°C : Degrees Celsius

CAMP : Continuous Airworthiness Maintenance Program

CASO : Civil Aviation Safety Officer

CASR : Civil Aviation Safety Regulation

CPL : Commercial Pilot License

COM : Company Operation Manual

CRM : Cockpit Recourses Management

CSN : Cycles Since New

CVR : Cockpit Voice Recorder

DFDAU : Digital Flight Data Acquisition Unit

DGCA : Directorate General Civil Aviation

DME : Distance Measuring Equipment

EEPROM : Electrically Erasable Programmable Read Only Memory

EFIS : Electronic Flight Instrument System

EGT : Exhaust Gas Temperature

EIS : Engine Indicating System

FL : Flight Level

F/O : First officer or Copilot

FDR : Flight Data Recorder

FOQA : Flight Operation Quality Assurance

GPWS : Ground Proximity Warning System

hPa : Hectopascals

Hrs : Hours

v

ICAO : International Civil Aviation Organization

IFR : Instrument Flight Rules

IIC : Investigator in Charge

ILS : Instrument Landing System

ITB : Institut Teknologi Bandung /

Institute of Technology, Bandung

Kg : Kilogram(s)

Km : Kilometer(s)

Kts : Knots (nm/hours)

Mm : Millimeter(s)

MTOW : Maximum Take-off Weight

NM : Nautical mile(s)

KNKT/NTSC : Komite Nasional Keselamatan Transportasi / National

Transportation Safety Committee

PIC : Pilot in Command

QFE : Height above airport elevation (or runway threshold

elevation) based on local station pressure

QNH : Altitude above mean sea level based on local station pressure

RESA : Runway End Safety Area

RPM : Revolution per Minutes

R/W : Runway

ROV : Remotely Operated Vehicle

SCT : Scattered

S/N : Serial Number

SSCVR : Solid State Cockpit Voice Recorder

SSFDR : Solid State Flight Data Recorder

STC : Supplemental Type Certificate

TS/RA : Thunderstorm and rain

TAF : Terminal Aerodrome Forecast

TPL : Towed Pinger Locator

TSN : Time since New

TT/TD : Ambient Temperature/Dew Point

UTC : Universal Time Coordinate

VFR : Visual Flight Rules

1

INTRODUCTION

SYNOPSIS

On 1 September 2010, a Cessna 172 aircraft, registered PK-ROG, operated by Bali

International Flight Academy (BIFA), based in Letnan Kolonel Wisnu Airfield Buleleng,

Bali

1

, conducted series of “touch and go” training at Blimbingsari Aerodrome, Banyuwangi,

East Java.

After three times touch and go, the pilot noticed that the oil temperature begun to fluctuate but

the other engine parameters indicated normal. At the fifth touch and go, the oil temperature

was steady at the top of the red band. The Instructor decided to discontinue the training and

return to Buleleng.

The aircraft was on flight return to the home base. While climbing and passing 500 feet

AMSL, the instructor noticed that the engine oil pressure begun to drop below the green band,

and at 700 feet the engine lost its power.

The Instructor contacted Blimbingsari ATS informed the situation and intention to make a

forced landing.

The aircraft landed in rice field at about 2.4 km South West of Blimbingsari Aerodrome. The

aircraft stopped with upside down position.

One pilot instructor and two student pilots evacuated the aircraft. The instructor and one

student were suffered minor injuries.

1 Letnan Kolonel Wisnu Airfield also known as Buleleng Airfield, Bali will be mention as Buleleng for the purpose of

this report.

2

1 FACTUAL INFORMATION

1.1 History of the Flight

On 1 September 2010, a Cessna 172 aircraft, registered PK-ROG, operated by Bali

International Flight Academy (BIFA), the aircraft was certified as being airworthy

prior departure, conducted a series of “touch and go” training at Blimbingsari

Aerodrome (Banyuwangi, East Java). On board in this flight were the flight instructor

and two student pilots.

Bali International Flight Academy (BIFA) was based at Letnan Kolonel Wisnu

Aerodrome at Buleleng, Bali. The touch and go training was conducted at

Blimbingsari Aerodrome at Banyuwangi, East Java, which was located approximately

22 Nm. The flight from Buleleng to Blimbingsari normally takes about 18 minutes.

The positioning flight to and from Blimbingsari was consider as part of the training

schedule.

After 3 times touch and go, the pilot noticed that the oil temperature begun to fluctuate

but the other engine parameters indicated normal. At the fifth touch and go, the oil

temperature was steady at the top of the red band. The instructor decided to

discontinue the training and return to Buleleng.

At 00:03 UTC

2

(07:03 LT),

the pilot requested to Blimbingsari Air Traffic Services

(ATS) to return to home base with intended altitude 1500 feet. The instructor acted as

pilot flying for this sector.

During climb at altitude 500 feet AMSL, the engine oil pressure begun to drop slowly

below the green band and continued to drop to the red band.

At 700 feet the engine lost the power.

At 00:06, the pilot contacted Blimbingsari ATS informed the situation and the

intention to make a forced landing. Approximately one minute later the engine

completely stopped and the pilot attempted to make a forced landing.

At 00:08,

Blimbingsari ATS lost contact with the aircraft. The rescue and fire fighting

personnel and vehicles from Blimbingsari Aerodrome started to search the aircraft

referring to the last reported position.

PK-ROA, a Cessna 172, another BIFA aircraft that was conducting training at the same

aerodrome, decided to assist the search for PK-ROG. At 00:13 UTC, PK-ROA departed

from Blimbingsari Aerodrome.

2 The 24-hour clock used in this report to describe the time of day as specific events occurred is in Coordinated Universal

Time (UTC). Local time, Western Indonesian Standard Time (WIB) is UTC+ 7 hours.

At 00:25, the pilot of PK-ROA found the location of PK-ROG wreckage and informed

Blimbingsari ATS.

PK-ROG was found landed in rice field at about 2.4 km south west from Blimbingsari

Aerodrome. The aircraft stopped with upside down position.

The Rescue and Fire Fighting personnel reached the location and found all PK-ROG

occupants have evacuated the aircraft. The instructor and one student suffered minor

injuries.

Figure 1: PK-ROG on rice field about 2.4 km SW from Blimbingsari Aerodrome

1.2 Injuries to Persons

Injuries Flight crew Passengers

Total in

Aircraft

Others

Fatal - - - -

Serious - - - -

Minor 2 - - -

None 1 - - -

TOTAL 3 - - -

1.3 Damage to Aircraft

The aircraft was substantially damaged.

• The wing, landing gears, engine and propeller remained attached to the fuselage

wreckage.

• The propeller blades were bent backward.

• The aircraft empennage area was buckled.

• The nose gear was collapsed.

• The aircraft left wing tip was bent.

3

4

1.4 Other Damage

There was a minor damage to the rice field.

1.5 Personnel Information

1.5.1 Pilot in command (Instructor Pilot)

Gender : Female

Date of birth : 21 February 1961

Nationality : USA

Marital status : Married

Date of joining company : September 2008

License type :

Commercial Pilot License

Valid to : 16 October 2011

Aircraft type rating : Cessna 172

Instructor rating : Valid

Instrument rating : Valid

Medical certificate : Class 1

Date of medical : 28 July 2010

Valid to : January 2011

Last line check : 21 August 2010

Last proficiency check : 21 August 2010

Flight Time

Total hours : 7,177 hours

This make and model : 4,756 hours

Last 90 days : 143 hours 51 minutes

Last 60 days : 86 hours 24 minutes

Last 24 hours : 4 hour 50 minutes

This flight : 50 minutes

1.5.2 Student Pilot

Student 1

Gender : Male

Date of birth : 11 May 1983

5

Nationality : Indonesian

Marital status : Married

Date of joining company : September 2009 (as student)

License type :

Student Pilot

Valid to : 30 September 2011

Aircraft type rating : Cessna 172

Medical certificate : Class 2

Date of medical : 30 September 2009

Valid to : 30 September 2010

Flight Time

Total hours : 13 hours 30 minutes

This make and model : 13 hours 30 minutes

Last 90 days : 13 hours 30 minutes

Last 60 days : 13 hours 30 minutes

Last 24 hours : 50 minutes

This flight : 20 minutes

Student 2

Gender : Male

Date of birth : 5 August 1987

Nationality : Indonesian

Marital status : Single

Date of joining company : September 2009 (as student)

License type : Student Pilot

Valid to : 14 September 2011

Aircraft type rating : Cessna 172

Medical certificate : Class 2

Date of medical : 14 September 2009

Valid to : 14 September 2010

Flight Time

:

Total hours : 12 hours 55 minutes

This make and model : 12 hours 55 minutes

6

Last 90 days : 12 hours 55 minutes

Last 60 days : 12 hours 55 minutes

Last 24 hours : 1 hour 55 minutes

This flight : 45 minutes

1.6 Aircraft Information

1.6.1 General

Aircraft Registration : PK-ROG

Country of Manufacturer : USA

Manufacturer : Cessna

Type/ Model : 172P

Serial Number : 17274614

Date of Manufacture : 1981

Certificate of Airworthiness : 2767

Valid to : 12 July 2011

Certificate of Registration : 2767

Valid to : 5 July 2011

Time Since New (TSN) : 8,079 hours 14 minutes

Last Minor Inspection : 100 hours dated 16 Aug 2010 at

aircraft TSN 8,061 hours

1.6.2 Engines

Engine type : Piston engine

Manufacturer : Lycoming

Model : O-320-D2J

Serial Number : L-13049-39A

Time Since New (TSN)

: 7,526 hours 13 minutes

Time Since Overhaul (TSO)

: 1,088 hours 44 minutes

The Operator has altered the use of avgas to mobile gas with refer to the FAA

Supplemental Type Certificate (STC) number SE2587CE, at 26 August 2010 (1 hour

39 minutes prior to occurrence) and conducted a ground run and flight test. There was

no engine setting changed required.

7

1.6.3 Propeller Information

Propeller type : Fixed pitch

Manufacturer : McCauley

Model : 1C160/DTM755M1

Serial Number : TK105

Time Since Overhaul

: 414 hours

1.6.4 Weight and Balance

The aircraft was being operated within the approved weight and balance limitations.

1.7 Meteorological Information

Wind : 270/05

Visibility : 7 km

Weather : Hazy

Cloud : Scatter 020

TT/TD : 25

o

C

QNH : -

QFE : -

1.8 Aids to Navigation

Not relevant to this accident.

1.9 Communications

The flight crew had no difficulty communicating with air traffic control during the

flight.

1.10 Aerodrome Information

Aerodrome Name : Blimbingsari

Aerodrome Identification : -

Coordinate : 08˚ 18’38” S; 114˚ 20’25” E

Elevation : 240 Feet (AMSL)

Airport Operator : Directorate General of Civil Aviation

Airport Category : Unattended aerodrome

Runway Direction : 08 / 26

Runway Length : 1400 metres

Runway Width : 30 metres

Surface : Asphalt

1.11 Flight Recorders

The aircraft was not fitted with a flight data recorder or cockpit voice recorder.

Neither recorder was required by current Indonesian civil aviation regulations.

1.12 Wreckage and Impact Information

An impact mark was found on a tree branch, located about 34 metres from main

wreckage.

Ground mark on the rice field trailed from the tree up to the main wreckage.

No debris spread or fuel smell or evidence of fuel spill on the ground within trail mark.

The aircraft stopped in up-side down likely due to impacted to a boundary pile.

Direction of flight

Figure 2: The aircraft’s propeller and nose landing gear were damaged

8

1.13 Medical and Pathological Information

There was no evidence of physiological factors affected the pilot performance.

1.14 Fire

There was no indication of pre or post impact fire.

1.15 Survival Aspects

This accident was survivable.

1.16 Tests and Research

Not relevant for this investigation.

1.17 Organisational and Management Information

Aircraft Owner : PT. Bali Widya Dirgantara

Aircraft Operator : PT. Bali Widya Dirgantara

Trading as : Bali International Flight Academy (BIFA)

Pilot School Certificate Number : 141/005

Head of School

Quality Control

Librarian

Chief Ground Instructor Chief Flight Instructor Chief Maintenance

Figure 3: Organisation structure

9

1.18 Additional Information

1.18.1 The Engine Teardown and Examination

1.18.1.1 Engine Teardown

The engine teardown was performed at the BIFA facilities in Buleleng, Bali, under

supervision of the NTSC investigators.

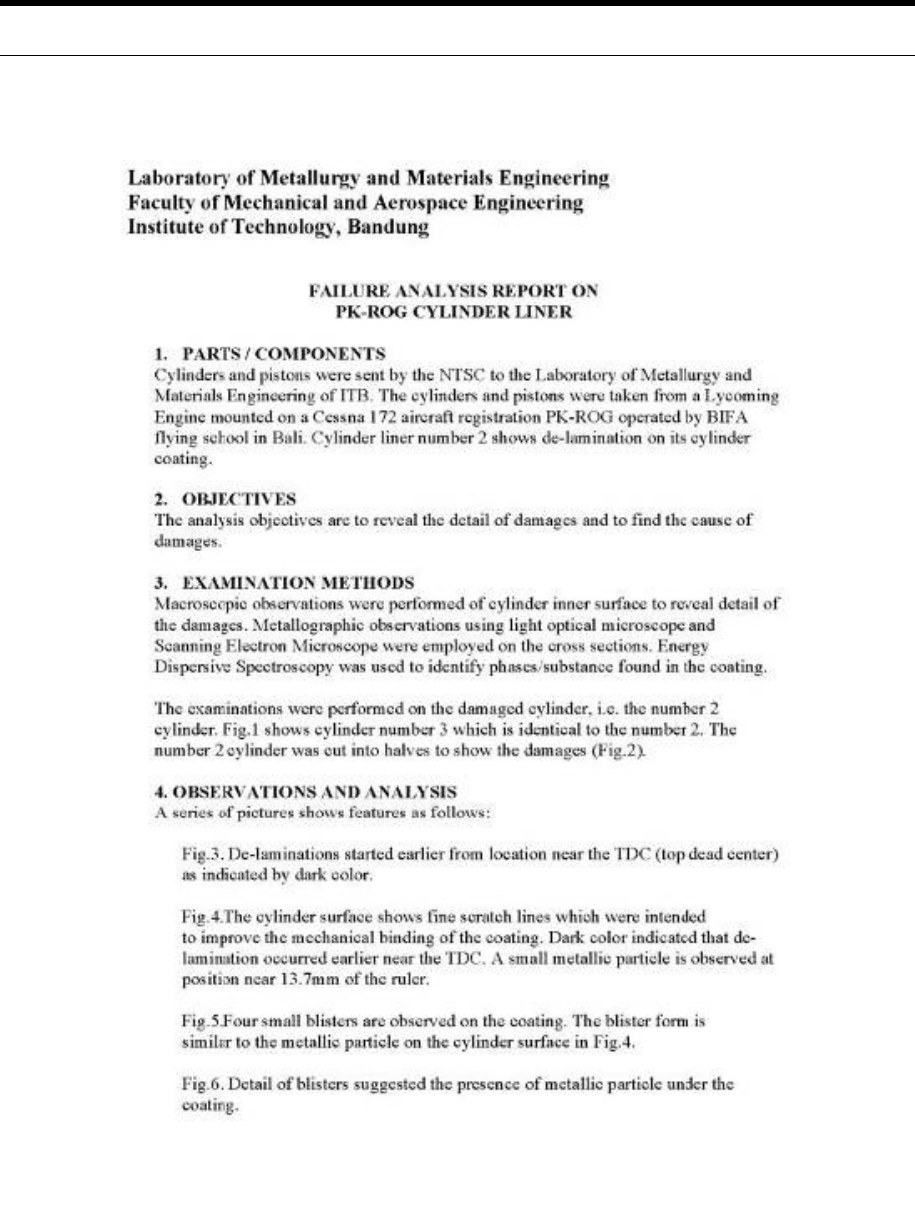

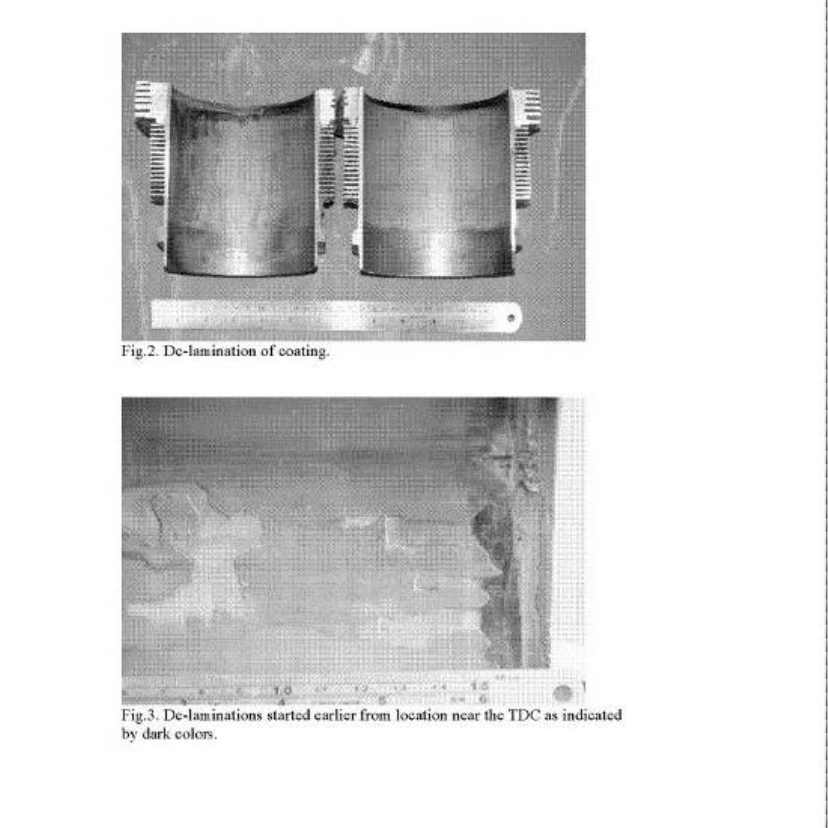

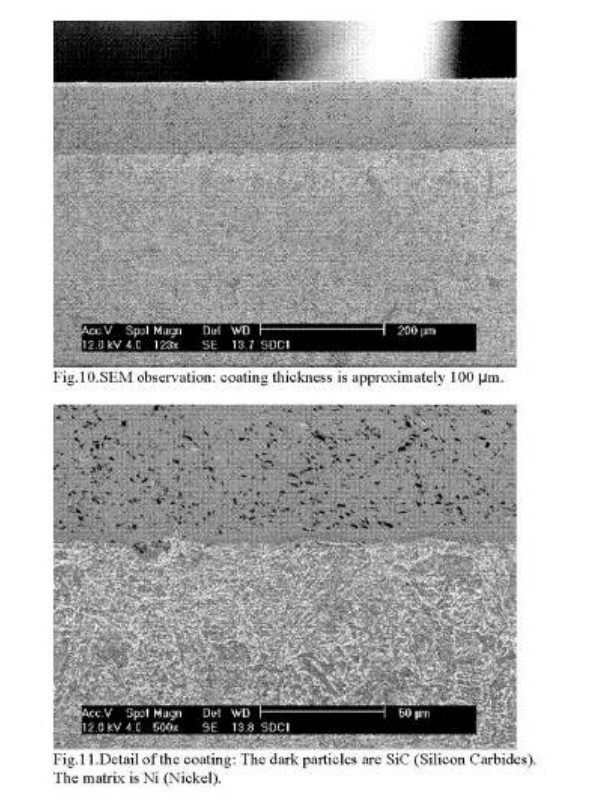

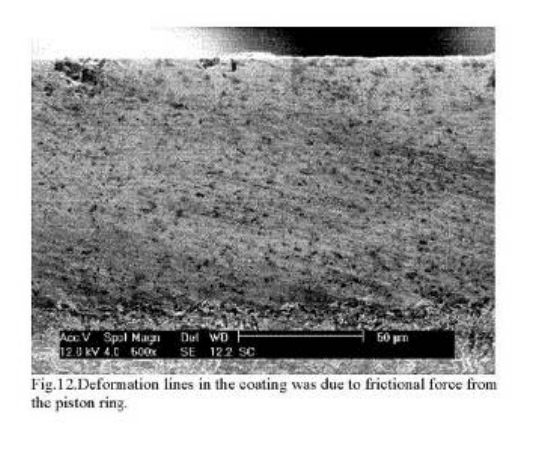

On the engine cylinder block #2, it was found that some scratches and de-lamination

of the coating materials on the inner side, and the piston crown discoloured.

1.18.1.2 Cylinder #2 Examination

The cylinder #2 was examined at the Laboratory of Metallurgy at the Institute of

Technology, Bandung.

From observations data, two main points that can be drawn are as follows:

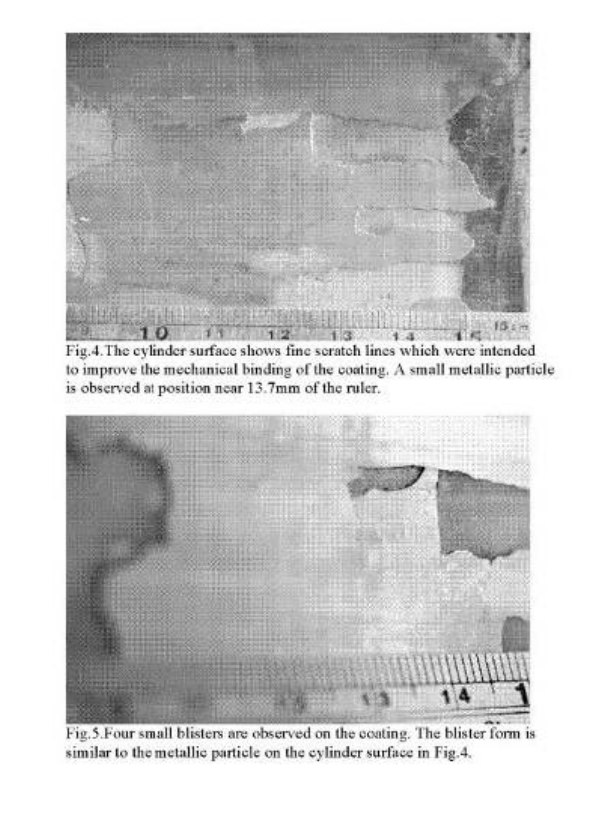

• The coating de-lamination started earlier from the location near the TDC (Top

Dead Centre).

• Blisters were found on the coating. It suggested that foreign particles /

materials were presence on the cylinder liner surface before coating deposition.

It suggested also that the surface preparation during manufacturing was not

properly done.

Figure 4: De-lamination of coating.

10

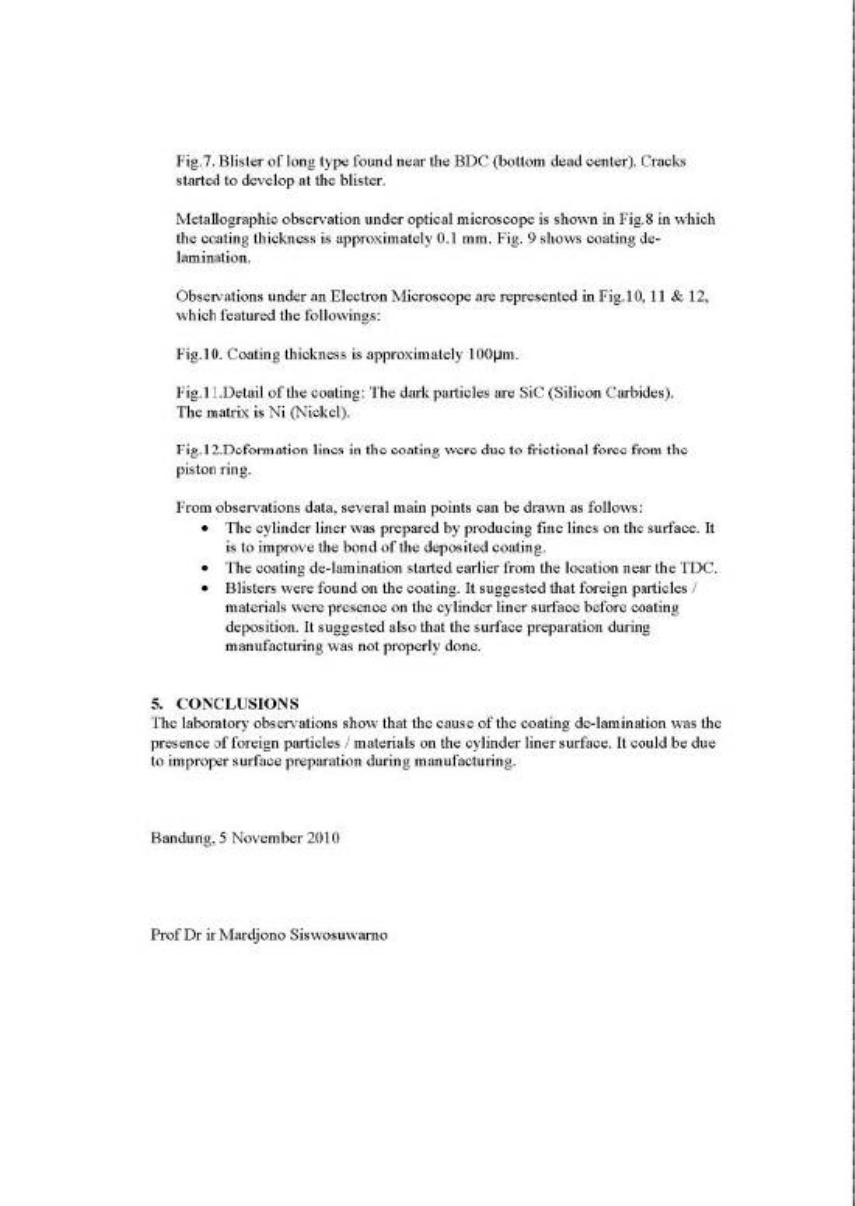

Figure 5: De-laminations started earlier from location near the TDC as indicated

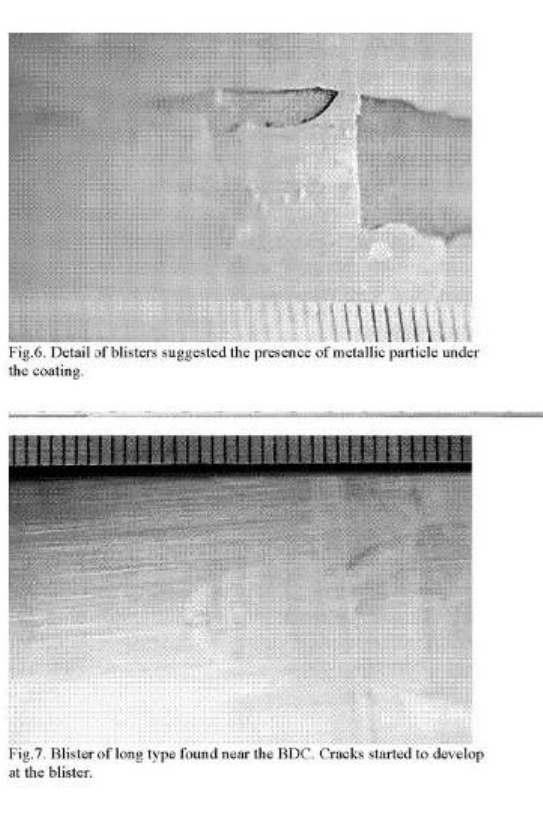

Figure 6: The cylinder surface shows fine scratch lines which were intended to improve the

mechanical binding of the coating. A small metallic particle is observed at position near

13.7mm of the ruler

11

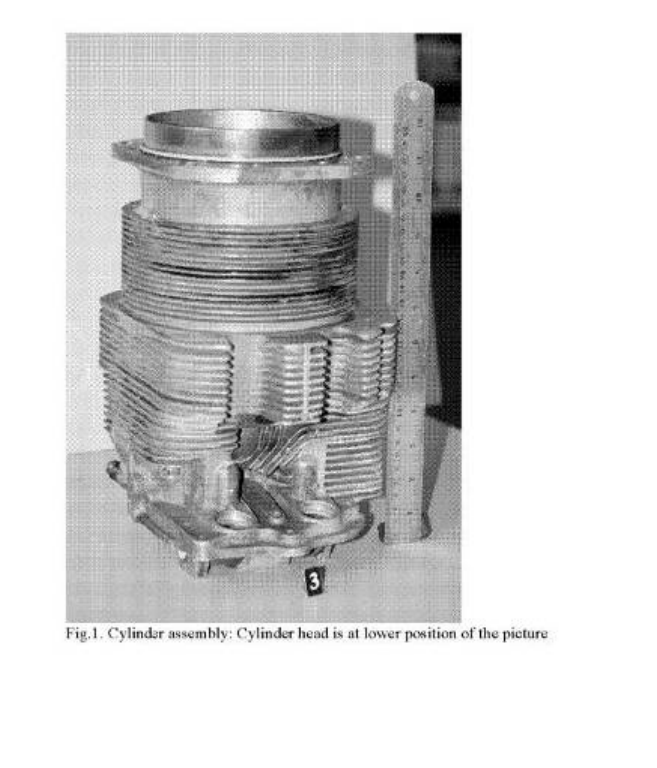

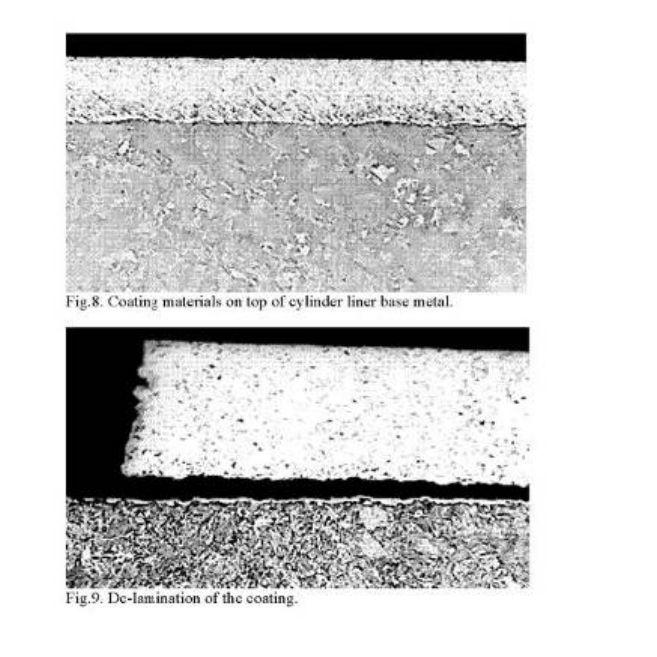

Figure 7: Blister of long type found near the BDC (Bottom Dead Centre). Cracks started to

develop at the blister

1.18.2 Maintenance

The Operator has altered the use of avgas to mobile gas with refer to the FAA

Supplemental Type Certificate (STC) number SE2587CE, at 26 August 2010 and

conducted a ground run and flight test. There was no engine setting changed required.

The Ignition Timing was set on 25

o

before Top Dead Center (TDC). There was also

information from another operator set the ignition timing on 23

o

before TDC for

Mobile Gas (Mogas).

The STC required that the minimum octane number to be used is 91. The fuel

laboratory test showed that the Mogas used had an octane number of 95.

1.18.3 Training Manual and Operation

The Training Manual

The investigation found one of the student pilots had qualified for solo flight, who has

not been trained for Emergency Procedure drill.

Refer to BIFA Training Procedure Manual, the Emergency Procedure drill should be

trained prior to first solo flight.

The Quality Control Section

Refer to BIFA Training Procedure Manual Chapter 2.2.2, responsibility of the Quality

Control section was to ensure that all training conducted by BIFA were in compliance

to all policies and procedures in the Training Procedure Manual and related CASR

(CASR Part 141, 61 and 91).

12

13

One of the Quality Control section duties was to carry out an internal audit and

surveillance at least once in every six months.

The investigation could not find any evidence of internal audit or surveillance

conducted by Quality Control section.

1.18.4 Fuel Handling Procedure

During the course of investigation, it was found that the mobile gas intended to be used

in the aircraft was transported to Blimbingsari base by a truck labelled “SOLAR” or

HSD (high-speed diesel). Furthermore, the aircraft fuel was stored in unsecured drums.

The fuel stored at Blimbingsari base were intended to be used for BIFA aircraft which

conduct training at Blimbingsari area which may required additional fuel. Normally,

the aircraft conducts training at Blimbingsari were carries sufficient fuel for the

duration of training from Buleleng.

1.19 Useful or Effective Investigation Techniques

The investigation is being conducted in accordance with the NTSC approved policies

and procedures, and in accordance with the standards and recommended practices of

Annex 13 to the Chicago Convention.

14

2 ANALYSIS

2.1 Engine Failure

The problem reported that the engine oil temperature was fluctuating, several moments

later; the engine temperature was steady at the top of the red band. The oil pressure

decreased slowly and the engine lost its power.

On the engine cylinder block #2, it was found that some scratches and de-lamination of

the coating materials on the cylinder liner, and the piston crown was discoloured (See

Appendix A).

Features of the damages on the cylinder liner #2 were as follows:

• The coating de-lamination started earlier from the location near the TDC (Top Dead

Centre).

• Blisters were found on the coating. It indicated that foreign particles / materials

were presence on the cylinder liner surface before coating deposition. It indicated

also that the surface preparation during manufacturing was not properly done.

The de-lamination of the cylinder liner decreased the engine power due to leakage of the

combustion gas into the crank-case. Consequently, the engine temperature increased, the

oil pressure decreased and the engine power decreased significantly and finally the

engine quit.

2.2 Fuel Alteration

The operator has altered the use of avgas to mobile gas with refer to the FAA

Supplemental Type Certificate (STC) number SE2587CE, at 26 August 2010 (1 hour

and 39 minutes prior to occurrence). There was no engine setting change required.

The STC required that the minimum octane number to be used is 91. The fuel laboratory

test showed that the Mobile gas used had an octane number of 95.

The fuel alteration was not a factor of the engine failure. If the fuel affected engine

performance, it should be observed during the ground run and flight test.

2.3 Fuel Handling Procedure

The method of transports Mogas fuel in the fuel truck that have been used to transport

any other type of fuel, may cause contamination to the aircraft Mogas fuel.

Storage of Mogas fuel in unsecured drums, may cause condensation and contamination.

15

3 CONCLUSIONS

3.1 Findings

• The instructor held a valid licenses and ratings for the operation of the aircraft.

• The aircraft was certified as being airworthy prior departure.

• The aircraft conducted a forced landing in a rice field and resulted the aircraft

landed in upside down position.

• The wing, landing gears, engine and propeller remained attached to the fuselage

wreckage.

• The Blimbingsari aerodrome Rescue and Fire Fighter Services were operated

during the search and rescue for this accident.

• The aircraft‘s engine oil pressure begun to drop below the green band and

continue drop to the red band.

• Pilot decided to discontinue the training and return to home base when the engine

oil temperature indication was steady at the top of the red band.

• The engine cylinder block #2 experienced de-lamination on the liner and over-

heated on the piston crown.

• The de-lamination of the coating of the cylinder #2 was caused by improper

manufacturing process, and accelerated by an excessive heat produced by the

detonation.

• The operator altered the use of avgas to mobile gas with refer to the FAA

Supplemental Type Certificate (STC) number SE2587CE, on 26 August 2010 (1

hour and 39 minutes prior to occurrence).

• The STC required that the minimum octane number to be used is 91. The fuel

laboratory test showed that the Mobile gas used had an octane number of 95.

There was no engine setting change required.

• The fuel alteration was not a factor of the engine failure. Had the fuel affected

engine performance, it should be observed during the ground run and flight test.

16

3.2 Causes

The problem reported that the engine oil temperature was fluctuating, several moments

later; the engine temperature was steady at the top of the red band. The oil pressure

decreased slowly and the engine lost its power.

The causes of the engine failure as follows:

• The engine cylinder block #2 experienced de-lamination on the liner and over-

heated on the piston crown;

• The de-lamination of the coating of the cylinder #2 was caused by improper

manufacturing process, and accelerated by an excessive heat produced by the

detonation.

17

4 SAFETY ACTIONS

After the accident, the NTSC issued some recommendation on Safety

Recommendations Letter No. KNKT/267/XI/REK/10 dated 23 November 2010 and

Letter No. KNKT/268/XI/REK/10 dated 24 November 2010.

4.1 Bali International Flight Academy

To response NTSC recommendation, Bali International Flight Academy had released

safety actions as follow:

a. Conducted one time inspection for all BIFA fleet related to the inner the inner wall

cylinder for the probability of scratch and delimitation;

b. Conducted one time inspection for all BIFA fleets related to fuel and air mixture

setting;

c. Temporarily stop usage of the mobile gasoline and re-use aviation gasoline;

d. Conducted recurrent training for maintenance engineers and mechanics, specific

for adjustment test and engine performance;

e. On December 2010, the BIFA changed their key management personnel, included

the Quality Control Section personnel.

4.2 Directorate General of Civil Aviation

To response NTSC recommendation, Directorate General of Civil Aviation had

released safety actions as follow:

a. On 27 December 2010, DGCA issued Safety Circular No. AU/10824/ DKUPPU/

5032/EK/V/XII/2010 related to Lycoming piston engine cylinder head inspection.

This Safety Circular instructs to all operators of Lycoming piston engine installed

cylinder assembly part number AE 65102, cylinder head part number AEL

85099IR to inspect the inner wall cylinder for the probability of scratch and

delimitation. The Safety Circular must be conduct by operator within 60 days, and

submit the inspection result to DGCA. At the time of issuing this Report, the

DGCA had not been informed of any discrepancies related to Lycoming piston

engine cylinder head inspection.

b. On 4 March 2011, DGCA issued Safety Circular No. No. AU/2088/

DKUPPU.1000/EK/VI/III/2011, related to Aircraft Fuel Storage, Handling and

Dispensing Procedure.

This Safety Circular instructs all operator to made or review their manual and

procedure about fuel storage, handling and dispensing procedure in according with

Staff Instruction 8300 Chapter 135 and Chapter 227, CAP 748, FAA Ac no.

150/5230-4A and ATA Specification 103.

18

5 SAFETY RECOMMENDATIONS

As a result of this investigation, the National Transportation Safety Committee issues

the following recommendations to address safety issues identified in this report

5.1 Recommendations to Bali International Flight Academy (BIFA)

The National Transportation Safety Committee recommends that the Bali International

Flight Academy (BIFA):

1. The emergency procedure training should be given to all student pilots prior to

first solo flight as described in the Training Procedure Manual;

2. Ensurred that the Quality Control section should performed the duty and

responsibility as described in the Training Procedure Manual;

3. Transportation of mobile gas fuel should be in the dedicated fuel truck and should

not be used to transport any other type of fuel. Fuel storage should be used secured

fuel drums.

5.2 Recommendation to the Director General of Civil Aviation (DGCA)

The National Transportation Safety Committee recommends that the Directorate

General Civil Aviation:

1. On 27 December 2010, DGCA issued Safety Circular No. AU/10824/ DKUPPU/

5032/EK/V/XII/2010 related to Lycoming piston engine cylinder head inspection.

This Safety Circular instructs to all operators of Lycoming piston engine installed

cylinder assembly part number AE 65102, cylinder head part number AEL

85099IR to inspect the inner wall cylinder for the probability of scratch and

delimitation. The Safety Circular must be conduct by operator within 60 days, and

submit the inspection result to DGCA;

2. On 4 March 2011, DGCA issued Safety Circular No. No. AU/2088/

DKUPPU.1000/EK/VI/III/2011, related to Aircraft Fuel Storage, Handling and

Dispensing Procedure. This Safety Circular instructs all operator to made or

review their manual and procedure about fuel storage, handling and dispensing

procedure in according with Staff Instruction 8300 Chapter 135 and Chapter 227,

CAP 748, FAA Ac no. 150/5230-4A and ATA Specification 103.

6 APPENDIX

Appendix A: Failure Analysis Reports on PK-ROG Cylinder Liner

19

20

21

22

22

23

24

25

26

27